OUR MISSION

Manufacture modern, reliable replacement engines that reignite general aviation and reduce our environmental footprint.

Updates

OUR MISSION

Manufacture modern, reliable replacement engines that reignite general aviation and reduce our environmental footprint.

11/2022:

C172 Experimental Update

8/2022:

UPDATE: Student Pilot Earns Private Pilot License in experimental Cessna.

11/2022:

Pilot Earns Commercial Pilot Certificate in experimental Cessna.l Update

11/2022: C172 Experimental Update

8/2022: UPDATE: Student Pilot Earns Private Pilot License in experimental Cessna.

9/2021: Pilot Earns Commercial Pilot Certificate in experimental Cessna.

AIRCRAFT ENGINES EVOLVED..

Aluminum Engine

Flex Fuel & AVGAS

25% Quieter

Operation: $21/ hour

TBO 3000 Hours

Lead-Free Emissions

Performance

Redundant Electronic Fuel Injection

PUSH BUTTON START

NO CARBURATOR HEAT.

NO MIXTURE.

NO RUN UP.

JUST FLY...

CORSAIR POWER

Corsair replacement engines for piston-powered general aviation aircraft incorporate modified aluminum V8 engine blocks and modified components. These features greatly increase aircraft performance, and allow the use of multiple fuel types. Corsair engines cut the harmful tailpipe and noise emissions while reducing operating costs up to 60% compared to original engines such as standard O-320 through O-540 legacy engines. Lower noise emissions will make quieter cockpits and happier neighbors. Corsair engines are more than 1/3 quieter than the legacy engines they replace!

REFI

The Corsair proprietary Redundant Electronic Fuel Injection (REFI) system eliminates the need for mixture or carb heat by monitoring dozens of engine and ambient temperatures and pressures to deliver optimum engine efficiency with every movement of the FADEC throttle. Each REFI system has its own critical sensors, fuel pump, fuel pressure regulator, fuel filter, and battery to assure reliable engine operation. The AUX EFI system is capable of completely returning a failed engine to normal operations within 1 second should the main EFI or its components fail.

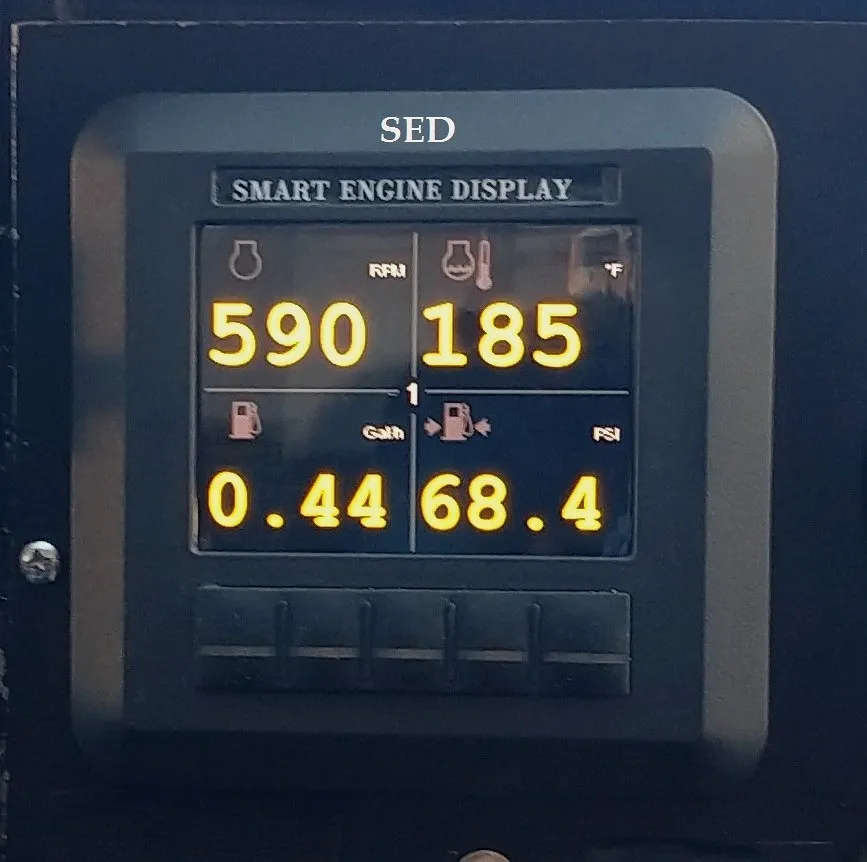

Smart Engine Display (SED)

The Smart Engine Display (SED) can replace all original analog gauges and reduce pilot work-load by alerting pilots to dozens of potential faults. The SED also displays fuel flow, fuel consumed and fuel quantity with customized alerts. The SED’s maintenance page displays live data for everything from fuel pressure to manifold temperatures, supporting engine health tracking and diagnosis.

The Engine Service Manual (ESM) contains troubleshooting & repair procedures for each code to expedite service and get airborne again quickly.

Prop Gear Drive (PGD)

System matched PGD allows both the engine and prop to operate at their most efficient speed (RPM), producing optimum performance, efficiency, and lower noise emissions. A metallic chip detector and temperature sensor are constantly monitored by the REFI and SED, which tracks trends and display alerts if outside operating limitations or when service is required.

The PGD is tested to BSHP and torque forces over 3 times that of the Corsair engine limits. It requires only routine servicing such as oil changes and visual inspections.

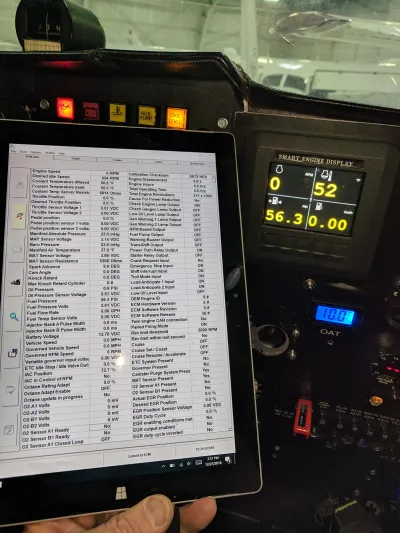

AEDS

ADVANCED DIAGNOSIS SOFTWARE

In addition to the SED maintenance page, Corsair optional diagnosis software for laptop or tablets displays live engine, fuel and electrical systems data. The software stores hundreds of parameters, as well as fault codes, with direct links to the respective engine service procedure. Additionally, components such as fuel pumps can be commanded on or off to check operation and aid in effective troubleshooting.

This capability can also allow Corsair technicians to remotely connect with your engine from anywhere in the world via WiFi or Bluetooth for escalated service issues.

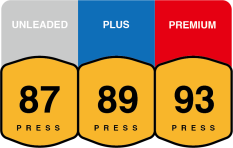

MULTIPLE FUELS

Corsair engines are flex fuel certified, allowing use of several different fuel types, including automotive (MOGAS, minimum 85 octane, with or without ethanol) available from any gas station. E15-E85 fuel requires optional fuel sensor. Leaded AVGAS is also approved, but MOGAS produces cleaner tailpipe emissions, is lead-free, cheaper, widely available and extends times between oil and spark plug servicing. The REFI system analyzes fuel type, and/or mixture of fuel, as well as tail pipe gases to adjust ignition and fuel delivery for optimum performance…….just like any modern car engine.

Multiple fuels allow aircraft operation in areas where AVGAS availability is scarce or not economically feasible worldwide.

PUSH BUTTON START

The engine start button automatically starts the engine within a second- no more frustrating moments of finessing or pumping the throttle, fine-tuning the mixture or running the battery down. Vapor lock is eliminated, so even hot engines start with the push of a button.

FLIGHT TESTING

The C172 engine test program has over 400 hours of successful and uneventful testing, with hundreds of induced failures and faults, in extreme weather conditions, with several fuel mixtures, and some very hard landings.

Shown Below: This is one of our many test videos. After takeoff, the main fuel pump, main battery and main ignition systems are failed causing an abrupt engine failure. Then, immediately, the AUX fuel pump automatically turns on and the redundant AUX ignition system returns the engine to full power and normal operations within 1 second of activation. The flashing yellow alert on the engine display includes a description of fault(s). If the engine experienced fault(s) that prevent the engine from producing full rated power, the alert would be displayed in red.

INFLIGHT ENGINE FAIL VIDEO

Shown Below: This video records multiple induced engine failures during approach segment. Initially, the main fuel pump is failed causing the automatic powering of the AUX pump (this happens quickly with no noticeable indications).

The AUX pump system at 3:17:50 on video is then completely de-powered causing engine failure; prop windmills. The AUX EFI system is activated and engine restarts within .55 seconds using wind-milling prop rotation (no starter motor engagement). The failed main EFI system is re-selected and engine again fails as aircraft slows below prop rotation speed and prop rotation stops.

With the main EFI, main fuel pump, and main electrical system failed, the AUX EFI system is selected and starter motor is momentarily powered only by the AUX battery. The engine restarts in less than 2 seconds utilizing only AUX system components.

Aircraft continues approach to landing, takeoff and climb on AUX power only……. with a 900 FPM climb rate at a density altitude over 7000 feet.

Corsair 1969 C172K vs. New C172S (Hot Weather Performance)

60 %

Reduced Operation Costs

6

Fuel Types

40 %

Less Emissions and No Lead

8,000 ft.

Full Rated Power Ceiling

CONVERTING TO CORSAIR

Firewall Forward

Our initial production engine, the ALPHA 1, will be available as an experimental crate engine, or as a complete bolt-on firewall forward conversion kit for common certified airframe models, starting with the C172.

Firewall forward kits for certified aircraft will include all components required for conversion, including complete engine with mount, PGD, prop, wiring harness, fuel system, batteries, and SED. Engines will be test run before shipping. Our target price point is the same as reman cost of original engine with original engine trade-in/core value.

The ALPHA X2 crate engine will be a complete system-matched power plant for experimental amateur and kit built airframes. We can customize the engine and prop to your requirements, and even perform final engine tuning remotely over a WIFI connection if needed.

Although Corsair is seeking FAA STC certification as a replacement engine for certified airframes, initial focus will be foreign customers for STC conversion kits- due to domestic liability issues of certified aircraft. Kits for certified aircraft types may be available to domestic operators within the ‘restricted’ or ‘POA’ airworthiness categories, or converting to the experimental category.

Economics

Corsair engines reduce direct hourly operating cost (fuel burn + oil consumed + engine reserves) up to 60% compared to original engines they replace. Our C172’s cost less than $21/hr to operate compared to over $60/hr with the original 0-320 Lycoming engine. Savings are further augmented as replacement parts typically cost 40%-60% less than legacy engine parts. Click here for more

A Corsair conversion makes old aircraft practical and fun to fly again, while outperforming the newest models in cost, performance, technology, and cleaner emissions.

Foreign customers, POA operators, and restricted operators needing certification information, please send us an email for specific information.

Please check our website for updates, and thank you for your interest.

Corsair is also seeking established dealers to sell, install, and support our products. Click here for info

We are seeking investment from qualified investors to assure Corsair’s climb to success. Click here for info